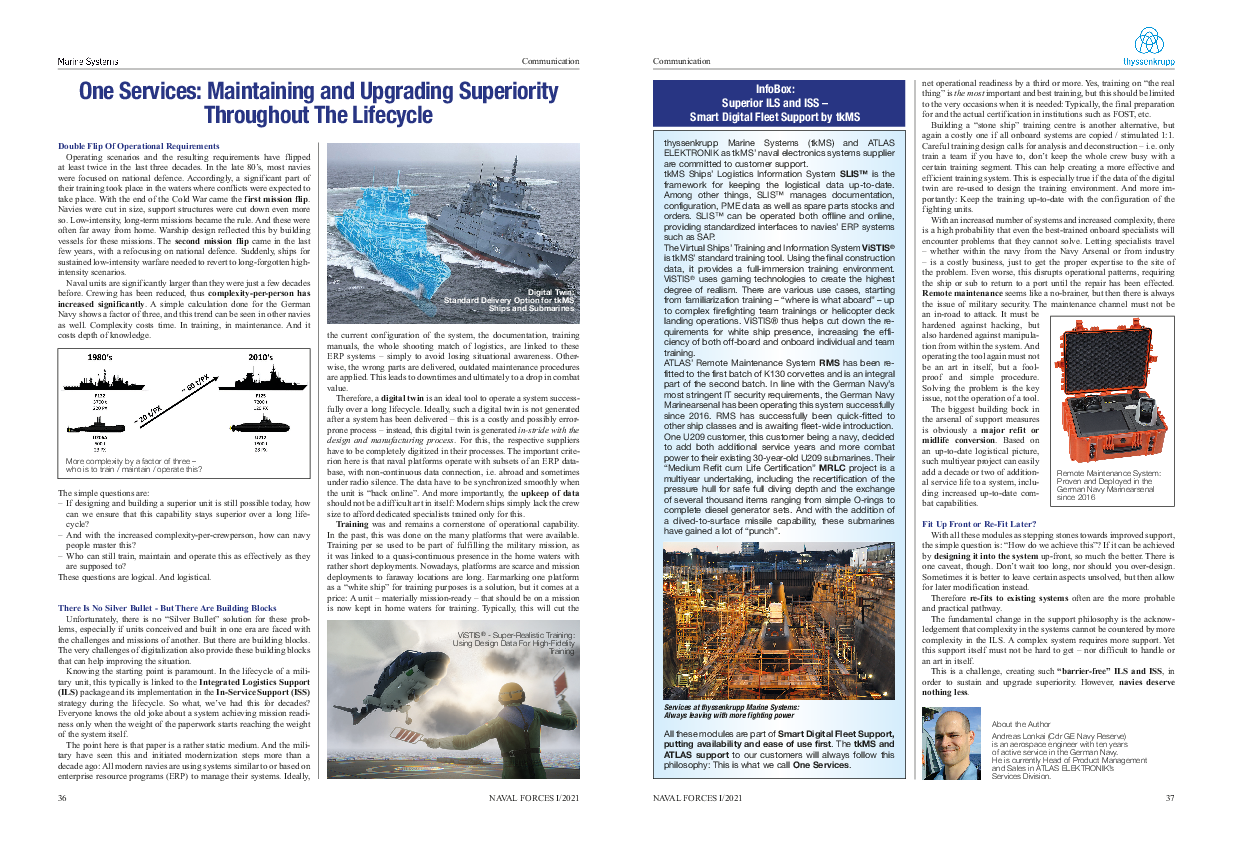

Proven, Deployed and IT-Secure Remote Maintenance System

Maritime security should be independent of pandemics. Therefore, most navies try to keep up their operational schedules, even though Covid-19 has serious effects, especially on the land-based support processes. In the worst case, travelling bans and a defect not repairable with onboard expertise could bring the mission to a standstill.

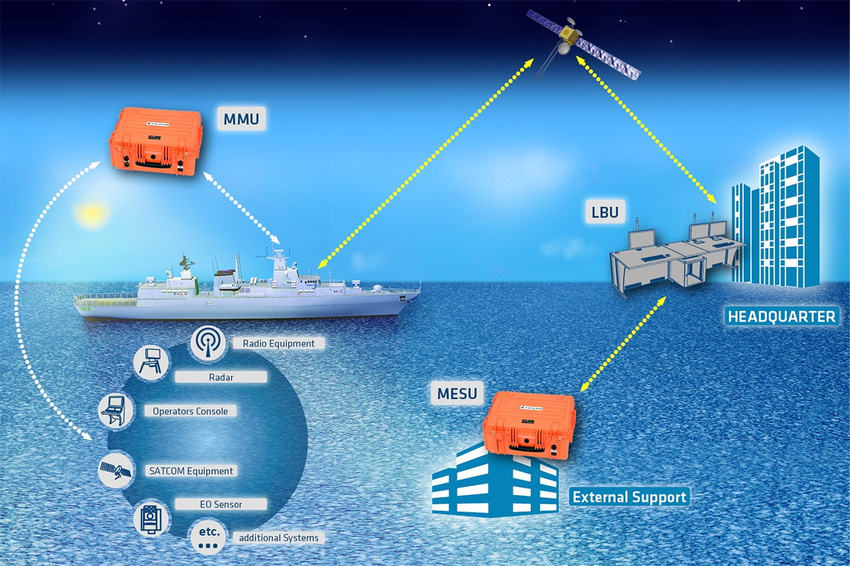

The German Navy has been operating ATLAS’ Remote Maintenance System (RMS) for years on their K130 corvettes. The RMS system allows the experts of Marinearsenal Wilhelmshaven to access a defective unit via an encrypted video-voice-data connection – with minimal bandwidth requirements. Linked together by the encrypted and IT-secure connection through SATCom, the onboard maintainers can talk directly to their depot level maintenance experts back home.

SERVICES: Sustaining Superiority

The Remote Maintenance System is just one building block in our integral services and support philosophy, which is highly customer-focused: We sustain superiority. Other building blocks are for example user-friendly designs with intuitive human-machine interfaces or easy and simple access to documentation, that keeps in-stride with configuration changes.

A comprehensive overview of our integral service philosophy is shown in the January 2021 edition of NAVAL FORCES magazine, aiming at strengthening our customers’ service capabilities. The German Marinearsenal Wilhelmshaven proudly demonstrate their improved service capabilities with M3C in the recent Marineforum edition. M3C “Marine MArs Maintenance Channel” is the German Navy’s internal name for RMS.